Precision Positioning Linear Systems

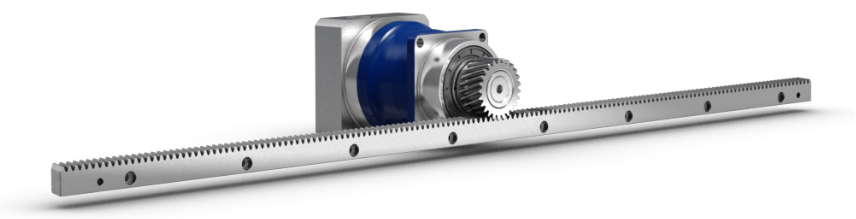

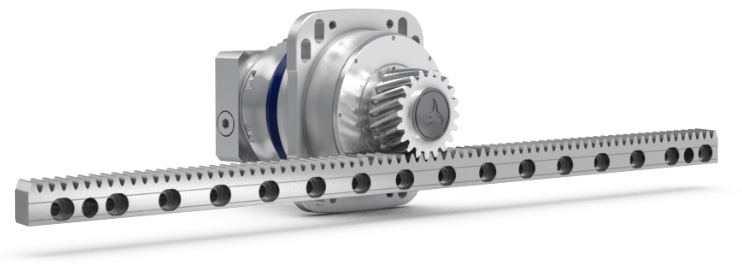

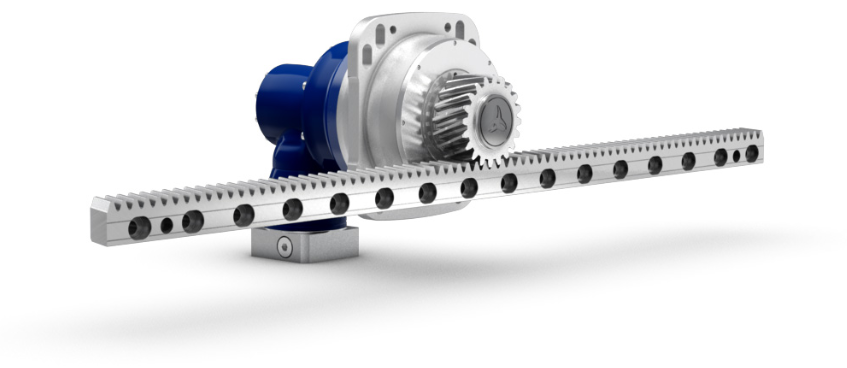

Linear systems provide a wide range of assembly solutions, from high-precision axes in manufacturing systems to packaging machines, which must operate at maximum productivity in the smallest installation space. Alpha linear products can be used in wood, plastic, composite materials, plasma cutters, automation, and other applications. HVH offers advanced, premium, value, and straight-toothing alpha linear systems.

HVH Industrial works with manufacturers' specialized engineering teams to meet our customers' requirements and highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Precision Positioning Linear Systems

Manufacturers

What Are Precision Positioning Linear Systems?

Precision positioning linear systems are mechanical devices designed to provide precise and controlled linear motion along a defined path. They consist of a combination of components, such as linear guides, drive mechanisms, and feedback sensors, which work together to achieve high levels of accuracy and repeatability.

How Do Precision Positioning Linear Systems Work?

The working principle of precision positioning linear systems involves converting rotary motion into linear motion using various mechanisms like ball screws or linear motors. These systems rely on precise motion control algorithms and feedback sensors to ensure the desired position is achieved and maintained throughout the operation.

Advantages of Precision Positioning Linear Systems

High Accuracy and Repeatability

Precision positioning linear systems offer exceptional accuracy and repeatability, ensuring that the same position can be achieved consistently, even after multiple cycles of operation.

Increased Productivity and Efficiency

By minimizing errors and providing reliable motion control, precision positioning linear systems enhance productivity and overall system efficiency, leading to cost savings and improved throughput.

Enhanced Safety and Reliability

In applications where human intervention is hazardous or impractical, precision positioning linear systems provide a safe and reliable alternative, reducing the risk of accidents and errors.

Applications of Precision Positioning Linear Systems

Industrial Automation and Robotics

In industrial automation and robotics, precision positioning linear systems are widely used to control the movement of robotic arms and automated machinery. They ensure that processes are carried out with precision, leading to increased productivity and reduced errors.

Semiconductor Manufacturing

In the semiconductor industry, where nanometer-level accuracy is essential, precision positioning linear systems are employed during the manufacturing process to handle delicate wafers and align microscopic components.

Medical Imaging and Healthcare

Precision positioning linear systems play a vital role in medical imaging equipment such as MRI machines, CT scanners, and X-ray systems. They allow for accurate patient positioning, leading to improved diagnosis and treatment.

Aerospace and Defense

In the aerospace and defense sectors, precision positioning linear systems are utilized in applications ranging from aircraft manufacturing to satellite positioning. Their ability to withstand harsh environmental conditions makes them suitable for such critical tasks.

Factors to Consider When Choosing a Precision Positioning Linear System

Load Capacity

The load capacity of the system should match the weight of the objects it needs to move. Choosing a system with insufficient capacity can lead to performance issues and premature failure.

Speed and Acceleration

Consider the required speed and acceleration of your application to select a system that can meet those demands while maintaining accuracy.

Environmental Conditions

In harsh environments, such as extreme temperatures or high levels of contamination, selecting a system with appropriate protective features is crucial to ensure reliable operation.

Cost and Budgetary Constraints

Evaluate the cost-effectiveness of the system concerning the specific application needs and budgetary constraints.

Conclusion

Precision positioning linear systems are a fundamental technology that drives advancements in various engineering fields. With their ability to provide accurate and controlled linear motion, they have become indispensable in industrial automation, semiconductor manufacturing, medical imaging, aerospace, and defense. Their advantages in terms of accuracy, productivity, and safety make them a preferred choice for numerous applications.