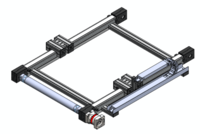

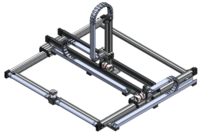

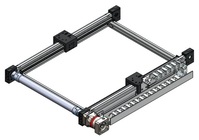

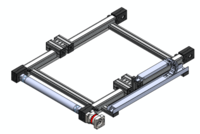

Linear Robots

Linear Robots are versatile, scalable, and simple multi-axis automation solutions that are widely used for sorting, packaging and palletizing, order fulfillment, pick and place, and automated manufacturing. They are designed to withstand rigorous daily usage, reduce design time, and speed up integration.

We offer a wide selection of Linear Robots including T-Bot Gantry Robots, H-Bot Gantry Robots, Dual Systems, Heavy Duty Dual Systems, X/Y Gantry Systems, X/Z Heavy Duty Gantry Robots, X/Y/Z Cartesian Gantry Systems, and X/Y/Z Heavy Duty Cartesian Gantry Systems.

HVH Industrial works with the specialized engineering teams of manufacturers to meet our customer's requirements and the highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Linear Robots

Manufacturers

Automation has become a driving force behind modern manufacturing processes, allowing companies to optimize productivity, enhance product quality, and reduce costs. Linear robots, also known as Cartesian or gantry robots, are at the forefront of this automation revolution. These machines consist of a three-axis system (X, Y, and Z) that can move objects along straight lines with precision and speed.

What are Linear Robots

Linear robots are mechanical systems designed to perform repetitive tasks in a highly efficient manner. They are composed of sturdy structures, precision actuators, and advanced control systems that work in harmony to achieve accurate and reliable movement. By utilizing linear guides, ball screws, and servo motors, linear robots can execute complex motions with exceptional accuracy, ensuring consistent performance even in demanding industrial environments.

Applications of Linear Robots

Sorting and Packaging

In the logistics and e-commerce industries, efficient sorting and packaging are essential for timely order fulfillment. Linear robots excel in these tasks by swiftly and accurately handling products of various shapes, sizes, and weights. With their high-speed capabilities and precise positioning, linear robots can significantly enhance productivity in warehouses and distribution centers.

Palletizing

Palletizing, the process of loading products onto pallets, is a common operation in many manufacturing facilities. Linear robots offer an ideal solution for palletizing tasks, as they can effortlessly stack products in predefined patterns. By automating this labor-intensive process, businesses can reduce costs, minimize errors, and improve overall efficiency.

Pick and Place

The pick-and-place operation involves selecting objects from one location and precisely placing them in another. Linear robots excel in this task, offering high-speed and precise movements. They are widely used in industries such as electronics, pharmaceuticals, and food processing, where delicate handling and precise positioning are critical.

Automated Manufacturing

Linear robots are extensively employed in automated manufacturing processes, where they enhance efficiency and productivity. They can perform tasks such as material handling, assembly, and quality control with remarkable precision and repeatability. By integrating linear robots into production lines, manufacturers can achieve higher throughput, reduce errors, and improve overall product quality.

Advantages of Linear Robots

Versatility

Linear robots are highly versatile, capable of adapting to various applications and industries. Their ability to handle various products, work in different environments, and perform multiple tasks makes them an ideal choice for businesses seeking flexible automation solutions.

Scalability

Linear robots offer scalability, allowing companies to expand their automation capabilities as their needs evolve. By adding more linear robots or integrating them with other automation systems, businesses can increase production capacity without significant disruptions or costly overhauls.

Simplicity

One of the notable advantages of linear robots is their simplicity. Their straightforward design and operation make them easy to install, program, and maintain. This simplicity translates into reduced training time, faster integration into existing workflows, and lower long-term maintenance costs.

Reduced Design Time

Linear robots come with standardized components and interfaces, which streamline the design and integration process. By leveraging pre-engineered modules, manufacturers can save valuable time during the implementation phase, allowing them to bring their automated systems to market faster.

Speedy Integration

Linear robots are designed with seamless integration in mind. They can easily interface with other machines, peripheral devices, and control systems, ensuring smooth communication and synchronization. This seamless integration facilitates efficient collaboration within the manufacturing ecosystem, further optimizing productivity and minimizing downtime.

The Impact of Linear Robots on Manufacturing

The introduction of linear robots has revolutionized the manufacturing landscape. These automation solutions have helped businesses achieve higher productivity, improve product quality, and reduce operational costs. Companies can allocate their workforce to more complex and value-added activities by automating repetitive and labor-intensive tasks. Furthermore, the precision and consistency provided by linear robots result in fewer errors and improve overall efficiency.

Conclusion

In conclusion, linear robots have emerged as essential tools for achieving efficiency, scalability, and reliability in modern manufacturing. Their versatility, scalability, and simplicity make them an attractive choice for businesses seeking automation solutions. By leveraging the power of linear robots, companies can enhance their competitiveness, meet growing customer demands, and unlock new levels of productivity in the dynamic world of manufacturing.